Understanding the Basics of Plastic Injection Molding Machines

Plastic injection molding machines are vital players in the manufacturing ecosystem, particularly in the production of plastic parts and components. This technology has evolved significantly, showcasing advanced features that enhance efficiency, accuracy, and overall production quality. As industries strive for better manufacturing outcomes, understanding these machines becomes crucial for optimizing production processes. When exploring options, plastic injection molding machine offerings undoubtedly provide comprehensive insights into the available technologies and their applications.

What is a Plastic Injection Molding Machine?

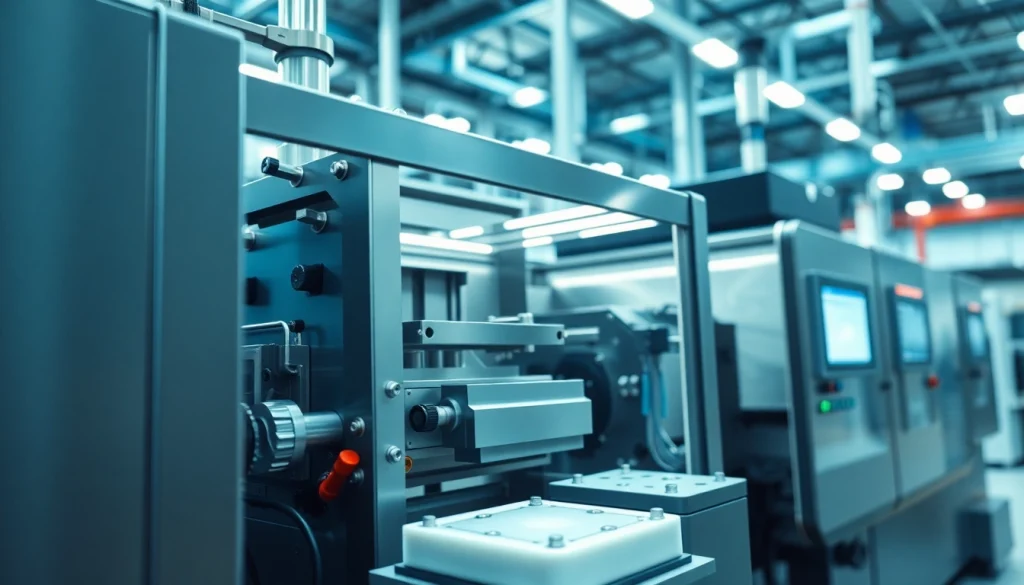

A plastic injection molding machine is an industrial machine used to manufacture plastic components through the injection molding process. It operates by melting plastic pellets and injecting the molten material into a mold, where it cools and solidifies into the desired shape. This process is widely employed in various sectors, including automotive, consumer goods, and medical devices, due to its ability to produce high-quality items at a rapid pace.

Key Components and Their Functions

Understanding the core components of a plastic injection molding machine is essential for evaluating its functionality and suitability for specific manufacturing needs. The main components include:

- Injection Unit: Responsible for melting and injecting the plastic material into the mold.

- Clamping Unit: Secures the mold in place during the injection process to ensure precision.

- Hydraulic System: Provides the necessary pressure for the injection and clamping processes, with hydraulic or electric options available.

- Mold: The custom-designed cavity that shapes the plastic into the final product.

- Control System: Manages the operation of the machine, allowing for precise control over various parameters.

Types of Plastic Injection Molding Machines

There are several types of plastic injection molding machines, each designed to cater to different production needs:

- Fully Electric Machines: Provide high precision, reduced energy consumption, and minimal maintenance.

- Hydraulic Machines: Offer high clamping force and are suitable for larger molds, though they are less energy-efficient.

- Hybrid Machines: Combine the benefits of electric and hydraulic systems, providing flexibility and efficiency.

Advantages of Electric Injection Molding Machines

Electric injection molding machines have gained popularity due to their numerous advantages, making them a preferred choice in many industries. Here are some key benefits:

Energy Efficiency and Cost Savings

One of the most significant advantages of electric injection molding machines is their energy efficiency. Unlike hydraulic machines that operate using pumps and hydraulic fluid, electric machines utilize servo motors to drive the injection and clamping processes. This results in lower energy consumption, leading to cost savings for manufacturers.

Precision Control and Product Quality

Electric machines offer superior precision control, which is crucial for producing high-quality plastic components. With discrete intelligent drive systems, they provide accurate positioning and pressure control, resulting in consistent product quality and fewer defects.

Integration with Automation Technologies

As industries move towards automation, electric injection molding machines seamlessly integrate with robotics and other automated systems. This integration enhances production efficiency and reduces labor costs, allowing for advanced manufacturing setups.

Challenges in Choosing the Right Injection Molding Machine

While the options for plastic injection molding machines are vast, choosing the right one can be challenging. Manufacturers must navigate several factors that influence their decision:

Understanding Production Requirements and Volume

Manufacturers should thoroughly assess their production requirements, including the volume of parts needed, the complexity of designs, and material types. This evaluation helps narrow down the type of machine that aligns with their operational needs.

Evaluating Cost versus Performance

Cost is a critical factor, but it should not be the sole consideration. Understanding the performance capabilities of each machine type is essential for long-term profitability. A more expensive machine may offer better performance and energy savings, which can offset initial costs.

Common Misconceptions in Equipment Selection

Many manufacturers hold misconceptions about plastic injection molding machines, such as assuming that larger machines are always better or that all electric machines are significantly more expensive than hydraulic ones. Educating decision-makers on the capabilities and limitations of different machines is vital for making informed choices.

Best Practices for Operating Injection Molding Machines

To maximize the performance and longevity of plastic injection molding machines, operators should follow best practices in their operation. Here are a few key practices to consider:

Maintenance Tips for Longevity and Performance

Regular maintenance is crucial for ensuring that injection molding machines operate efficiently. This includes:

- Conducting routine inspections for wear and tear.

- Lubricating moving parts as recommended by the manufacturer.

- Calibrating machines to ensure precision in production.

Optimizing the Injection Molding Cycle

Streamlining the injection molding cycle can significantly enhance productivity and reduce costs. Operators should focus on optimizing cooling times, injection speeds, and cycle times based on the material and product specifications.

Safety Protocols in the Production Environment

Maintaining a safe production environment is vital. Implementing strict safety protocols, including training operators on emergency procedures and ensuring that all safety guards are in place, can prevent accidents and injuries.

The Future of Plastic Injection Molding Machines

As technology continues to advance, the future of plastic injection molding machines appears promising. Here are some trends shaping the industry:

Emerging Trends in Automation and AI Integration

The integration of artificial intelligence (AI) and automation technologies is transforming the landscape of injection molding. By utilizing machine learning algorithms, manufacturers can predict maintenance needs, optimize production processes, and enhance quality control.

Sustainability Developments in Materials

With increasing emphasis on sustainability, manufacturers are exploring biodegradable and recyclable materials for injection molding. Innovations in materials science are leading to the development of eco-friendly plastics that reduce environmental impact.

Predictions for Industry Growth and Advancements by 2025

The injection molding industry is poised for significant growth over the next few years. By 2025, advancements in machine capabilities, energy-efficient technologies, and increased automation are expected to drive efficiency and reduce costs, ultimately benefiting manufacturers and consumers alike.